Liberation of this decade: using innovation to polish national automobile brands

From now on, FAW Liberation will launch a series of reports on "Endeavour for a New Journey, Liberation in the Decade", which will showcase the historic achievements of FAW Liberation since the 18th National Congress of the Communist Party of China in an all-round and multi-level manner. Firmly grasp the valuable experience of building a world-class enterprise, building a century-old national brand, and realizing high-quality development of liberation in the new era. Further consolidate the strength of forge ahead and bravely assume the mission of strengthening the country. Welcome the victory of the 20th National Congress of the Communist Party of China with practical actions.

Since the 18th National Congress of the Communist Party of China, FAW Jiefang has regarded innovation as the first driving force for development, adhered to innovation-driven, technology-leading, and industry-leading, and comprehensively created the core competitive advantage of its products. FAW Jiefang has placed independent innovation in a more prominent position and made significant progress in key core technology fields. Entering the new era, innovation has made the base color of "Jiefang", a national automobile brand, brighter.

Based on the market, product leadership

Products are the bedrock of an enterprise’s foothold. Over the years, FAW Jiefang has adhered to "one generation of production, one generation of research and development, and one generation of reserve". In 2017, with the merger of the Commercial Vehicle Development Institute, the enterprise’s R & D capabilities were further enhanced, and the business fields of "research, production, supply, and sales" were further connected. The transformation from "what is developed and produced" to "market to market" was realized, and the sales share continued to increase.

FAW Jiefang product pedigree

Over the past ten years, FAW Jiefang has accurately grasped market changes and user requests, increased R & D investment year by year, and quickly produced products and good products. It has successively launched a series of replacement products and key models, and created 12 product platforms covering heavy, medium and light trucks and buses. In the field of heavy trucks, J7, as the benchmark model of high-end heavy trucks in China, has a market share of 49%. It has won awards such as the first prize of China’s truck of the year in 2019 and the first prize of China’s automotive industry’s scientific and technological progress in 2020. As the latest high-end heavy truck of Jiefang, Yingtu has become a highlight of the industry with high-reliability power chain and intelligent home experience, and is sought after by the market. As a Jiefang knock-out product, J6P has continuously improved its family pedigree and expanded its market coverage. J6V focuses on customer value pain points and is committed to providing the best operation solutions for TCO. In the mid-card field, J6L, JK6, and Long V continue to build product competitiveness with customers as the center. Cargo products have continuously maintained the first market share in recent years. In the light truck field, we adhere to the efficient and lightweight strategy, vigorously promote the improvement of product portfolio and product competitiveness, and achieve rapid growth in the share of Lingtu, J6F, and Tiger V. In the bus field, the third-generation new energy smart bus has been put into the bus market in batches, and the Snow Eagle luxury off-road RV is about to be launched, which is highly anticipated by the market.

Over the past ten years, FAW Jiefang has continued to upgrade its product technology. In 2015, it took the lead in launching world-class warranty standards such as "three major assemblies 100,000 kilometers long oil change, wheel end 500,000 kilometers maintenance-free, and 3 years long quality assurance regardless of mileage". At the same time, it has also created a series of core technologies such as system fuel saving, independent electronic control, independent post-processing, lightweight, high reliability, low wind resistance, low rolling resistance, vehicle energy management, gas drive urea system, and high-efficiency post-processing technology, establishing an absolute leading advantage in technology. On this basis, through adaptive product development and improvement, FAW Jiefang has successively launched a series of new products such as Pilot Edition, Honor Edition, Quality Edition, Northern Edition, Southern Edition, Plateau Edition, Green Edition, and Express Edition, which have been widely welcomed by the market with their differentiated competitive advantage.

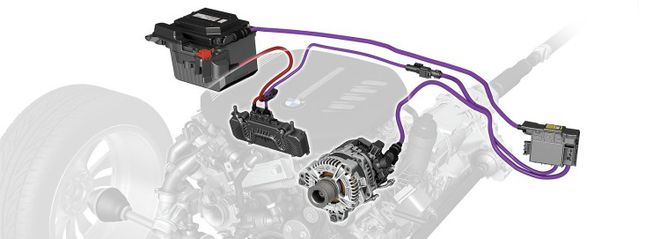

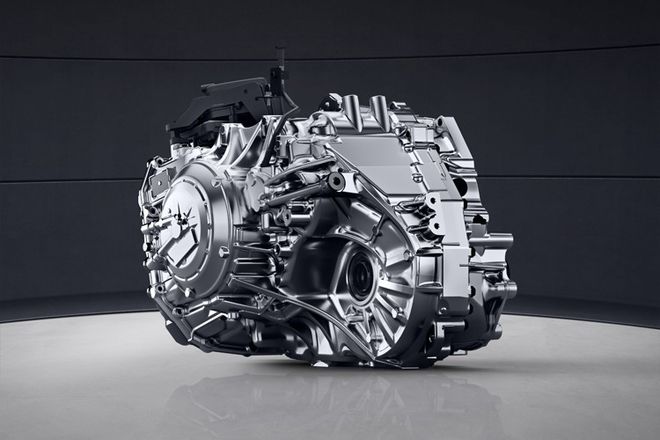

Over the past ten years, FAW Jiefang has adhered to the independent development of the three major assemblies. With the mission of creating low-carbon, digital intelligence, and high-reliability power, engine products have vigorously promoted Product Research & Development to create three heavy-duty, high-efficiency and energy-saving power platforms for diesel engines and natural gas for commercial vehicles M/V/X. The comprehensive competitiveness of the products is leading in the industry. Box bridge products have worked together to improve high-quality, lightweight, and low-TCO key technologies to fully meet market demand. They have successively launched a series of new products such as 12-speed manual transmission, automatic transmission, 435, and 465 drive axles, and continued to consolidate their independent competitive advantage.

Facing the future and accelerating transformation

In recent years, a new round of global scientific and technological revolution is on the rise, and the "New Four Modernizations" wave characterized by new energy and intelligent networking has swept the entire automotive industry. As a traditional manufacturing enterprise, FAW Jiefang aims to accelerate its own transformation in the direction of industrial development. On the basis of strengthening traditional models, it pays greater attention to and invests in new technologies and new formats. Product innovation and business innovation have achieved a series of results.

In September 2021, FAW Jiefang released the "15333" new energy strategy

FAW Jiefang actively implements the national "double carbon" strategy. In September 2021, it released the "15333" new energy strategy, sounding the "charge" of the transition to new energy. By building three major vehicle technology platforms of pure electricity, hybrid and combustion power, and three core assembly technology platforms of electric drive, power battery and fuel cell, it has successively developed a new high-safety and long-life hybrid battery system, fuel cell system integration technology, domestic first EPB hydraulic brake + E-Park, light independent coaxial integrated electric drive bridge and a series of products. On June 8, 2022, the independent hydrogen direct injection engine was successfully ignited, indicating that the thermal efficiency exceeded 55% and reached the international leading level. FAW Jiefang actively plans the strategic layout of new energy and builds a "sustainable and positive cycle" new energy ecosystem. Starting from the landing pilot in Shijiazhuang during the Jiefang era, it actively innovates the business and marketing model to create three exclusive services: vehicle and electricity separation, vehicle leasing and capacity undertaking, used car and battery recycling, and fully realizes a breakthrough in the new energy market. So far, a total of 141 new energy products have been launched, achieving industry leadership in the new energy track.

FAW Jiefang unmanned port vehicle is put into operation in Shandong Rizhao Port

In the field of smart vehicles, FAW Jiefang has also achieved fruitful results. In 2017, FAW Jiefang completed the first commercial vehicle driverless demonstration in China, and in 2018, completed the L4 series of smart vehicle product release demonstrations. In recent years, by comprehensively breaking through the core technology of intelligent network connection and building a leading intelligent network technology platform in China, FAW Jiefang has focused on key operation scenarios such as trunk logistics, sanitation, and ports to create 14 intelligent network connected commercial vehicle products and achieve the first sales volume in China, achieving comprehensive leadership in technology and products. The world’s first mass-produced L2-level and L3-level trunk logistics intelligent tractor, J7 super truck has accumulated 2.38 million kilometers of operation, and the first L4-level autonomous urban sanitation product based on 5G-V2X. It was the first to demonstrate operation in Suzhou High-speed Railway New Town, and has operated safely without accidents for more than 100,000 kilometers. The first car, port, cloud trinity driverless port vehicle operation system, the first in Rizhao port business operations, cumulative loading and unloading containers over 70,000 TEU.

In terms of vehicle to everything and ecology, the "vehicle to everything" vehicle to everything product has deepened the transformation of digital intelligence, completed the construction of vehicle to everything infrastructure, realized the standard configuration of all models vehicle to everything, and reached new highs in new formats. At present, more than 1.50 million commercial vehicles have been linked, and the accumulated mileage data exceeds 200 billion kilometers. Through vehicle to everything data, the APP provides users with vehicle information query, driving behavior analysis, one-click service and other functions, all of which have reached the industry’s leading level. FAW Jiefang also focuses on the core scene of the aftermarket, cross-border cooperation, and customized the development of the "Four Musketeers" ecological services of refueling, insurance, ETC, and fleet management. At the same time, it provides users with in-vehicle WIFI services to help the ecological services bloom in an all-round way.

Innovation leads, brave the trend

In recent years, FAW Jiefang has deepened the branding of "liberation and leadership" technology, and created three independent innovation technology routes: "Jiefang Zhitu", "Jiefang Lantu" and "Jiefang Yitu", focusing on the main direction of "four modernizations and one high" (informatization, intelligence, low carbon, electrification, high quality) technology. The number of technological development and resource investment have increased by more than 50% annually, and a number of key core technologies have made major breakthroughs. The company has successively won the second prize of the National Science and Technology Progress Award and the first prize of the China Automotive Industry Science and Technology Progress Award.

In September 2020, the first science and technology conference of FAW Liberation was successfully held

In 2020, FAW Jiefang successfully held the first science and technology conference and released the "Outline of FAW Jiefang Science and Technology Development Plan (2021-2030) ", which fully established the "13586" development plan. Taking technological innovation as the banner, FAW Jiefang has identified three "main channels" for technological development. Traditional vehicles lead the system to save energy and attack zero-carbon fuels. New energy vehicles realize the electrification of traditional vehicles in stages, the intelligence of core assemblies, and the exclusivity of vehicle platforms. Intelligent network pilot automatic driving and mining vehicles to everything. On this basis, a complete application technology and forward-looking technology layout have been further formed, setting the development direction for near and long-term technology leadership and product leadership. In recent years, FAW Jiefang has established R & D institutions in Suzhou, Nanjing, Foshan, Steyr, Austria, Munich, Germany, Japan and other places, forming a "four countries and nine places" R & D layout, making full use of the advantages of high-level talents in various places, and pooling global wisdom to enhance innovation capabilities.

In recent years, FAW Jiefang has actively expanded production-university-research cooperation and collaboratively carried out new technology research. It has strengthened cooperation with the Society of Automotive Engineering, academic organizations such as Tsinghua University, Shanghai Jiao Tong University, Jilin University, Wuhan University of Technology, and colleges and universities. Through the establishment of innovation platforms, research centers, innovation centers or laboratories, etc., it has accelerated the solution of industry technical problems, promoted the transformation and application of achievements, and made leapfrog progress in basic technology and forward-looking technology research, laying a solid foundation for technological leadership and product leadership.

At the same time, FAW Jiefang comprehensively optimized the technical project management procedures, constructed and implemented a scientific and technological innovation reward mechanism, and rewarded scientific and technological innovation projects, papers and authorized patents. From 2018 to 2021, 81 scientific and technological innovation projects, 67 scientific and technological papers, and 1,327 authorized patents were rewarded, with a total reward of 6.469 million yuan, benefiting 2,373 people. It won 1 second-class national scientific and technological progress award, 15 provincial and industry scientific and technological progress awards, and 40 group company scientific and technological progress awards. In 2022, it organized and completed 79 company-level scientific and technological innovation project applications and reviews, 30 recommended group scientific and technological innovation awards, 9 provincial-level awards, and 13 industry-level awards. Since 2020, the company has held the "Liberation and Innovation Technology Achievement Exhibition", "’3310′ Core Technology Achievement Exhibition" and "New Energy Vehicle and Assembly Technology Exhibition", fully demonstrating its innovation achievements and R & D strength.

In the future, FAW Liberation will thoroughly implement the spirit of the important speech of the Supreme Leader General Secretary’s inspection of FAW, unswervingly follow the path of independent development, open cooperation, adhere to the innovation-driven development strategy, and strive to play a greater role in promoting high-level scientific and technological self-reliance in the field of national commercial vehicles.